APAC seismic reinforcement materials market to garner 60% of the global share by 2025

Publisher : Fractovia | Published Date : 2019-07-16Request Sample

Seismic reinforcement materials market is slated to amass substantial returns in the years to come, owing to existing damages to old buildings and possibility of collapses, human and economic losses caused by devastating earthquakes. In recent times, the design of stronger structures and development of seismic technology in emerging economies like China, India and Japan, as well as across many developed countries has accelerated. This has increased the potential demand for key materials provided by seismic reinforcement materials industry.

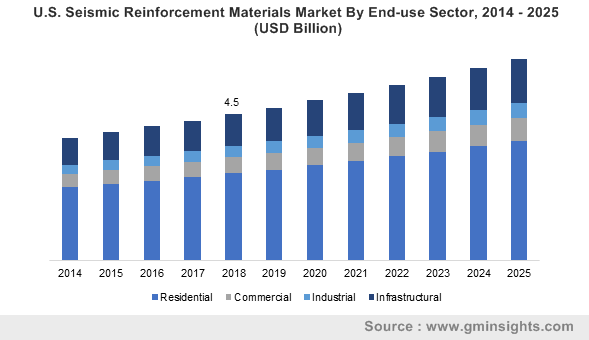

U.S. Seismic Reinforcement Materials Market By End-use Sector, 2014 – 2025 (USD Billion)

The rapid growth of population around the world impacts the economy as well as the environment massively, in terms of constructing tall, safe and long lasting buildings. Architects and engineers are testing and implementing applicable building codes like modifying structural steel to help improve earthquake resilience, adding transverse walls to the building structures, recycling Tetra Pak panels, bamboo and light concrete foundations. These unique implementations allow less carbon footprint and enhance the product demand from both commercial and residential sectors, strengthening seismic reinforcement materials industry outlook.

Advanced structural and earthquake engineering is playing a major role in enhancing the seismic flexibility of critical infrastructure and civil structures through the implementation of advanced engineering and equipment management. Civil engineers are irrefutably looking to adopt the latest anti-seismic technologies, considered to be quite popular for building structures that can withstand the vast majority of recorded earthquakes. Unquestionably, adopting these technologies will protect buildings on a large scale and construction companies would result in augmenting opportunities for seismic reinforcement materials market players globally.

Modern and energy-efficient buildings tend to grab headlines in Japan where earthquakes are a normal event. Japan has become a prime example of an earthquake ready country by creating structures with rubber, inflated, or fluid-filled basis for easily absorbing shock. Tokyo’s famous Skytree building was built to withstand natural disasters by representing the shape of ancient wood pagodas, which have lasted through centuries of earthquakes. From earthquake resistant designs to composite materials, civil engineers and designers have attempted to develop and adopt new forms of materials that would assist in the building of stronger, long lasting, and aesthetic structures.

Reportedly, a 2011 tsunami in Japan resulted in 121,778 buildings being totally collapsed, while another 280,926 buildings were half collapsed. The tsunami and accompanying earthquake had caused severe and extensive damage in north-eastern Japan including heavy damage to roads, railways, and dam collapses. Early estimates placed insured losses from the earthquake alone at US$14.5 to $34.6 billion. To ensure the safety of all passengers, Japan is ensuring that car and train bridges are earthquake-ready, besides developing bullet trains which are equipped with earthquake sensors that freeze every moving train in the country in case of a calamity.

Asia-Pacific has seen an increasing deployment of seismic reinforcement materials, automated earthquake warning alerts and others to tackle natural disasters. Reports estimate that Asia Pacific region will account for over 60% of the global seismic reinforcement materials market share by 2025. Earthquake prone countries in the region like India, China, Indonesia, Japan, Thailand, Philippines will further boost the regional demand considerably over the forecast period. Presence of domestic and international manufacturers has ensured a consistent supply of materials to the region, further fueling APAC seismic reinforcement materials market trends.

Improved understanding of structural response towards natural calamities like storms and earthquakes has resulted in the establishment of new design codes and standards to ensure continued reliability. In addition to materials like steel, concrete and timber, advanced composites can be deployed at relatively low costs and provide major advantages to the construction sector, opening up substantial prospects for seismic reinforcement materials industry in the forthcoming years.

Simpson Strong-Tie Company Inc, Hyundai Steel Company, West Fraser Timber Co. Ltd., ArcelorMittal, Toray Industries, Inc., LafargeHolcim Ltd., Tata Steel Limited, and BASF SE are some of the prominent players focusing on improving building reinforcement products in order to expand their global reach. Global Market Insights, Inc. has projected that seismic reinforcement materials market size will exceed USD 40 billion in valuation by 2025.