Regenerative blowers market valuation to hit the billion-dollar milestone by 2025, U.S. to observe increasingly intensive competitive portfolio

Publisher : Fractovia | Published Date : July 2018Request Sample

Endowed with a rich end-user landscape, regenerative blowers market is on its way to emerging as a highly lucrative business domain across the HVAC space. These blowers have found prominent applications across myriad industries to ensure contamination free air supply. However, given that they use oil for lubrication to perform the compression mechanism effectively, which can lead to oil contamination, industry biggies have been continuously conducting research activities for the enhancement of product operations. In addition, few of the giants in regenerative blowers industry are also enhancing their product portfolio by implementing new design strategies. Aided by the launch next-generation products, regenerative blowers market is likely to witness commendable gains in the ensuing years.

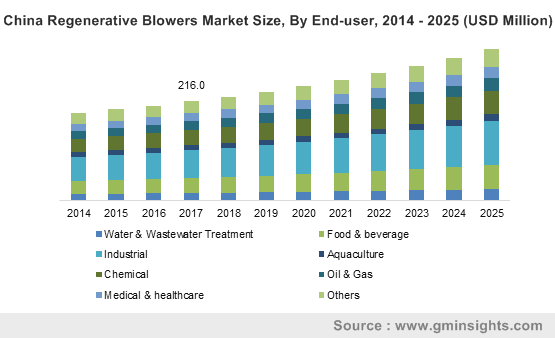

China Regenerative Blowers Market Size, By End-user, 2014 – 2025 (USD Million)

Enumerated below is a diversified approach of industry contributors toward product development that has been playing its part in augmenting the revenue graph of this business space:

Vairex Corporation: Focusing on cost-efficiency

Cost effectiveness is one of the prominent measures depicting the growing acceptance of products across myriad regions. Focusing on the affordability and quality parameters of blowers, the U.S. based company, Vairex Corporation had developed several variants of regenerative blowers around half a decade back. With the help of effective tooling operations, the company managed to reduce the manufacturing cost of the product while enhancing its quality.

Even in the current scenario, this strategy could help the American manufacturer attract many of the fuel cell system developers, given the availability of high quality products with lesser costs. Reportedly, most of Viarex’s products have been used in fuel cell systems that are deployed in electric vehicles. The shifting trends toward the deployment of emission free vehicles across various geographies have augmented the requirement of fuel cells which has ultimately had a positive influence on regenerative blowers industry share.

Becker Pumps Corporation: Focusing on performance enhancement

Performance improvement comprising less noise, compact size, and higher output is another notable aspect contributing to the expansion of regenerative blowers industry. As most of the regenerative blowers are extensively are used in water treatment, medical, and material handling applications for aeration, chip removal, pneumatic conveying, packaging, and printing operations where performance is always prioritized, regenerative blowers market contenders aim to improve operational performance, setting a novel benchmark for product development.

Validating the aforementioned fact, recently, Becker Pumps Corporation launched a new set of regenerative blowers with advanced features and enhanced performance. More precisely, for developing this new series of products, Becker has used the concept of reverse engineering which has helped the firm develop higher capacity blowers with less consumption of energy. Powered by the development of energy efficient single and two-stage regenerative blowers, Becker has successfully consolidated its position in regenerative blowers market.

Ametek DFS: Focusing on innovative product development

In order to achieve competitive benefits with the help of new design strategies, major participants in regenerative blowers industry are incorporating advanced technologies and high-flow designs in their products. In addition, they also plan to develop maintenance free blowers with greater airflow and greater efficiency. Merely a few months before, Ametek DFS developed a software assisted next-generation blower, which possesses remarkable features such as noise free operation, high airflow output, and fume evacuation. Ametek’s efforts clearly indicate that the incorporation of sensitive electronics modules in product designs can significantly customize the acceleration and speed of blowers, leading to improvement in operational flexibility.

Incidentally, the company has also added notable features such as a motor enclosure and cooling chamber with which blowers can operate at a low temperature, providing an extended shelf life. Newly designed products are thus gaining popularity pertaining to the addition of next-generation features. In essence, it is rather overt that the increasing deployment of technologically advanced product ranges is slated to fuel the market size over the years ahead.

Regenerative blowers are commonly used in many of the industrial and commercial applications for ensuring a small volume of air at higher pressure. The suitability of these products for clean air applications is thus attracting more consumers toward this vertical of late. In this regard, manufacturers are looking forward to offering an eco-friendly and economical product portfolio., driven by which regenerative blowers market will register a CAGR of 4.5% over 2018-2025.