Europe polyaryletherketone market to accrue USD 600 million by 2025

Publisher : Fractovia | Published Date : 2019-07-16Request Sample

Owing to the rising demand for engineering plastics and high-end compounds in the aerospace and automotive sectors, polyaryletherketone market has gained enormous traction over the past few years. Although traditional materials have been used to make key components for decades, engineers are now discovering new applications for the thermoplastic materials like polyetheretherketone (PAEK) and its variants which exhibit unique performance characteristics as compared to conventional plastics.

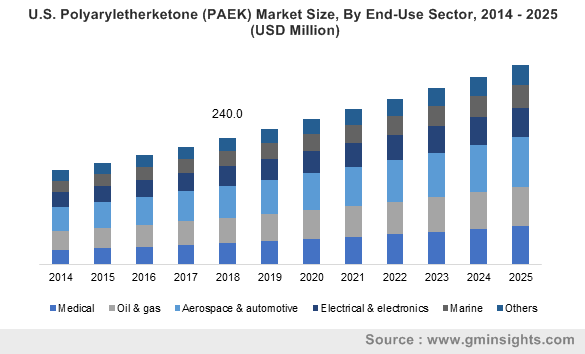

U.S. Polyaryletherketone (PAEK) Market Size, By End-Use Sector, 2014 – 2025 (USD Million)

Reinforced polymers have noticeably changed the way different types of airframes are designed and built today. Evolving trends like enhancing fuel economy, increasing the load-carrying capacity of airplanes and their maneuverability has stimulated extensive research towards the use of novel materials characterized by the good mechanical strength and low weight. PAEK is considered as an advanced and high-temperature engineering polymer that features excellent mechanical properties, thermal stability, and chemical resistance. Thermoplastics are increasingly being employed in aerospace composites include polyetheretherketone (PEEK) and polyetherketone (PEK).

Eminent studies suggest that the aircraft sector anticipates around 41,000 new and replacement aircrafts to be required by 2035 for meeting upsurge in passenger and cargo traffic. Growing adoption of lightweight materials that allow for low manufacturing costs and offer durability in harsh environments will boost global polyaryletherketone market size. Accomplishing this kind of mounting demand clearly calls for not only innovative technologies and new approaches towards production process, but also to incorporate thermoplastic composites such as PEEK.

Widespread use of high-performance thermoplastics for various aircraft applications is being observed, including bracket for luggage compartment retainers, seating & structural supports, nuts & bolts, vent grills, and pipes. More importantly, materials like PEEK add value beyond weight reduction for many applications, owing to unique properties like ease of manufacturing while meeting the challenging requirements of spacecraft and aircrafts. Majority of aircraft manufacturers seem to be investing towards R&D efforts to address any upcoming challenges, fueling polyaryletherketone market growth.

For instance, sensing an opportunity within the aerospace segment for PAEK materials, Victrex, a British-based supplier of high-performance polymer solutions had opened a Polymer Innovation Centre in 2017 at its facilities in Thornton-Cleveleys, near Blackpool, U.K. The plant was started with an aim to further research in PEEK and other grades of PAEK thermoplastics, particularly for building aviation composite parts. Such initiatives prove the considerable potential of PAEK to substitute traditional component materials. Estimates suggest that the expanding aerospace, automotive and marine segments will account for over 30% of global PAEK industry share over the next few years.

Speaking of automotive applications, Europe will be a major market for the global polyaryletherketone industry, given the rising presence of automobile manufacturers in the region. Most luxury vehicle manufacturers prefer to use PAEK in automotive components such as pistons and connectors, considering the demand for lightweight cars. As per estimates, Europe PAEK market size is expected to cross USD 600 million by 2025.

A prominent driver influencing the adoption of PAEK variants is the continuous attempts by companies to deliver stronger aircraft parts. TxV Aero Composites had received ISO 9001:2015 and AS9100 certification in 2019 for its highly automated thermoplastic composite parts manufacturing facility. Achievement of the certification demonstrated that the TxV management system complies with all the quality standards required for manufacturing composite parts of the highest quality for the commercial aerospace sector. Similar efforts to advance capabilities undertaken by key manufacturers will further fuel PAEK market trends.

Consistently rising cost of fuel and the push for lower ticket prices, in addition to emission control norms, have encouraged more airlines to acquire aircrafts which are as light as possible, without compromising on quality. With their corrosive resistance properties, light weight, and resistance to high temperature, plastic polymers are becoming a profound choice for the sector to replace materials traditionally made of metal alloys.

Rapid development of cutting-edge technologies like 3D printing and extensive investments in R&D programs indicate that the aerospace segment will generate lucrative business prospects for polyaryletherketone industry players. A burgeoning demand worldwide from the public transportation, defense and aviation sectors will augment global PAEK market share over the forecast timeframe.

Prominent players such as Ensinger, Triveni Chemicals Limited, Victrex, Mitsubishi Chemical Advanced Materials, Toray Advanced Composites and Panjin Zhongrun Chemical are some of the key PAEK supplies. Successful long-term alliances and cooperative research partnerships between airplane manufacturers and PAEK producers will further boost the industry size. Global Market Insights, Inc. forecasts polyaryletherketone market to surpass annual revenues of more than USD 1.5 billion by 2025.