Orthodontic supplies market growth to be majorly swayed by the proliferating 3D printing technology, global share to surpass USD 7 billion by 2024

Publisher : Fractovia | Published Date : 2018-08-30Request Sample

Bay Materials LLC, one of the leading orthodontic supplies market player, has recently made it to the headlines with its latest release of Zendura™ AT, reportedly, the first ever and only material engineered for fabricating aligner attachment templates. This advanced material allows more precise attachment placement and is able to capture the attachment details designed in software more concisely than most of the other materials. With Zendura AT offering finest fabricate attachment templates and enhancing patient experience, analysts deem Bay Materials to amass substantial revenue gains and strengthen its position in the global orthodontic supplies industry.

Japan Orthodontic Supplies Market, By Product, 2013 – 2024 (USD Million)

The above-mentioned instance also stands as a substantiation to the fact that major industry players are investing in developing the product portfolio constituting of clear aligner therapy (CAT). With the growing demand for more satisfying and comfortable method of orthodontic treatment, CAT continues to witness growth across the globe and particularly in the U.S. orthodontic supplies market. The significant rise in the number of adults and teens that demand for orthodontic treatments such as correction of dental malocclusions to enhance their physical appearance and oral health have been increasingly driving the regional market.

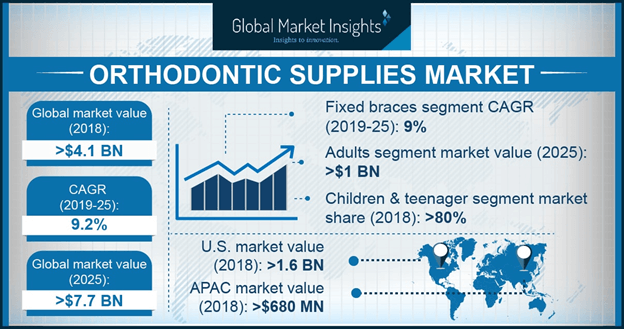

Technological advancements and favorable governmental policies have also had a positive impact on the growth prospects of this sector. Having garnered USD 1.5 billion in 2017, the U.S. orthodontic supplies market is expected to register a y-o-y growth of 8.8% over 2018-2024. U.S. being a technology hub, it also comes as no surprise that primarily on the account of the critical advancement in the 3D printing technology and digital dentistry, in the recent years, the region has garnered remarkable momentum across the regional landscape of orthodontic supplies industry.

3D printing, often referred as the next industrial revolution, is indeed transforming the way dental professionals such as orthodontists and pediatric dentists are producing prototypes and dental products. Orthodontic supplies industry, is one such domain where 3D printing has made itself most indispensable, especially for manufacturing clear orthodontic aligners, which can strengthen teeth alignment without the use of metal and uncomfortable wires. In fact, additive manufacturing has brought the mass production of customized aligners to a level that is anticipated to keep on growing rapidly. This has made both independent entrepreneurs and mainstream manufactures in the orthodontic supplies industry to increasingly look into 3D printing to carve out an individualized niche in the business space.

Clinicians have documented that 3D printing technology has helped dentists & patients regarding precise placements of attachments and has thus improve outcomes, expanding the market for clear aligner therapy to a wider range of cases. Pertaining to the discomfort of traditional braces, more and more orthodontics are turning to 3D printing for the manufacturing of dental aligners, on account of which companies are seeing a lot more business across this segment. One of the foremost 3D printers & material distributors EnvisionTEC claims that sales of their dental printers grew by 75% in 2016.

3D printing manufacturer, Structo, in this regard is significantly disrupting the orthodontic supplies industry space with its Mask Stereolithography-based 3D printers that are tailored for dental applications. These printers are now being used by top aligner brands such as ClearCaps, to lower the overall cost, streamline aligner productions, and in achieve a more accurate output. If reports are to be believed, Structo’s newest dental 3D printer called as the DentalForm, is touted to be the fastest dental model 3D printer across the globe. ClearCaps claim that Dental Form - capable of printing up to 10 clear aligner molds in over half an hour – has an impressive throughput rate and is therefore perfect for mass manufacturing of aligners.

Analyzing these competitive trends, it wouldn’t be wrong to quote that the impact of 3D printing technology on the orthodontic supplies industry has been dramatic. The new additive manufacturing industrial wave has not only uplifted the remuneration portfolio of this business sphere but has also helped immensely in mass production & customization of orthodontic products for children, teenagers, and adults. A report by Global Market Insights, Inc., further throws light on the future growth of this business sphere and anticipates the overall orthodontic supplies market to surpass USD 7 billion by 2024.