Mining machinery market to witness robust demand from underground mining equipment sales, surging deployment of autonomous technology to alter the industry dynamics

Publisher : Fractovia | Published Date : 2017-02-24Request Sample

Owing to the rapidly growing demand for automobiles, electronics, construction materials and industrial machines, the mining machinery market valuation has been soaring high over the last few years, with global revenues surpassing USD 70 billion in 2017. Rising consumption of commodities has encouraged companies to invest heavily into mineral exploration for replacing operations of soon to be depleted mines. The mining equipment industry has been able to cope with the mounting concerns regarding safety of miners and the required operational efficiency by evolving with constant advances in technology. Besides the existing mines that have huge amounts of annual output, there are a vast number of underground deposits being investigated to mine precious metals, ores and coal, which will enormously strengthen the global mining machinery market.

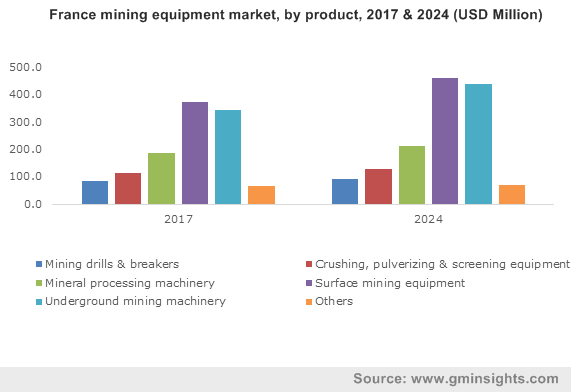

France mining equipment market, by product, 2017 & 2024 (USD Million)

The Mponeng mine near Johannesburg, which is the world’s deepest mine from the surface level, has operations running almost 4 kilometers below ground and is indicative of the vast amount of machinery and equipment that must be deployed. In a step that would bolster the mining equipment industry, the mine owners had commenced a study in 2017 into the feasibility of expanding operations at the mine which would extend its lifespan to 2050. Aiming to reach an output of over 450,000 oz of gold per year for the next 20 years, the project might cost around USD 1 billion spread over 10 years. As many other mining companies are seeking similar expansion projects over gold, copper as well as coal deposits across continents, the mining machinery market will experience fast-paced growth over the coming years.

With fast depleting mines threatening to disrupt the economic status of many communities, new mines are coming up and some companies are in the process of seeking approval from governments to begin underground mining. Whitehaven Coal, for instance, is looking to ramp up government approvals for tow new coal mines in Australia’s New South Wales, which could be a promising growth avenue for the country’s mining equipment industry. According to Whitehaven, the Winchester and Vickery mines will help the company to maximize productions levels as Australia’s high quality of coal exported to Asian markets is being supported by recovering coal prices. Even smaller countries that have an increased demand for power are looking to develop underground mining operations to meet the fossil fuel requirements.

Elaborating further, the government in Tajikistan, a country in Central Asia, had recently expressed a need for expanding underground coal mining for coping with internal needs of the people, as only two underground deposits had been explored so far. As per reports, twelve enterprises in the nation had been given a license for developing nine coal deposits and it can be surmised that the mining machinery market will see notable demand from underground mining in the country. Underground mining, undoubtedly, poses significant threats to the safety of personnel and equipment and the global mining segment is expected to adopt modern equipment and technology at a larger scale. Innovations in process automation and the influx of autonomous mining robots are thus steadily transforming the mining equipment industry worldwide. As per Global Market Insights, Inc., mining machinery market size from underground mining machinery is slated to register a CAGR of 6% over 2018-2024.

In terms of protecting the life of miners, innovative automated systems help to lower the risk involved not only in exploring deeper into mines but also during the transport of mineral ores to the surface. Advanced robots are being used to scan mines, analyze ore deposits, conduct mining operations and take the raw ore to loading bins. Australia-based Resolute Mining’s new Syama mine, located in Mali, would become the world’s very first fully automated mine, signifying the tremendous evolution achieved by the mining machinery market. Utilizing technology designed in collaboration with Sandvik, extensive fiber-optic network will be present to ensure that an uninterrupted connection is maintained between autonomous trucks and other automated elements.

Speaking father, Resolute estimates that by automating the mine, it would eventually be able to cut down mining costs by 30%. Demonstrating the massive impact which the underground mining machinery market could experience, the onset of automated machinery will help to minimize injury to miners, assist in training them better, carry out most of the dangerous tasks, while working efficiently in hazardous environments. As more mining corporations shift towards autonomous operations to improve their efficiency and lower operational costs, the mining machinery market is anticipated to witness robust demand over the coming years.