Long fiber thermoplastics market to gain significant impetus from sports applications, extensive demand for lightweight, durable material in automobiles & airplanes to drive the industry trends

Publisher : Fractovia | Published Date : May 2019Request Sample

The global long fiber thermoplastics market has found a significant driving force in the numerous research and innovation activities abound today, as the benefits of LFTs against traditional composite materials have become more pronounced. The qualities that set LFTs apart are weight reduction capability, enhanced structural strength and recyclability. Long fiber thermoplastics have been found to be beneficial in increasing manufacturing efficiencies as they are easier to use than traditional materials which also helps in streamlining processes.

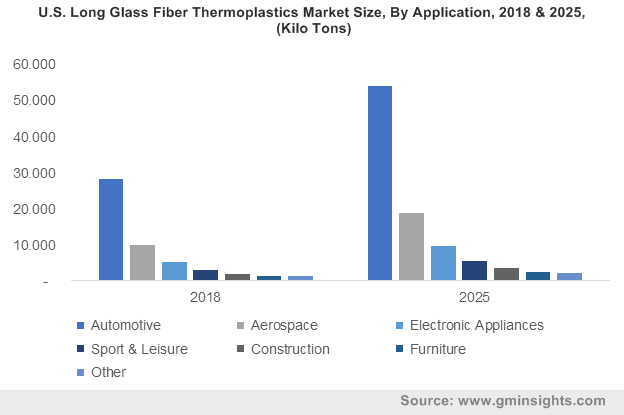

U.S. Long Glass Fiber Thermoplastics Market Size, By Application, 2018 & 2025, (Kilo Tons)

In addition, they are more flexible and can therefore be used in greater complex design geometries that cannot be so easily achieved by thermosets or metals. Though the usage of thermosets is more pervasive in the global composite material market, a gradual shift towards the use of thermoplastics has been observed due to the improved production cycles they offer while no compromise on quality is necessary. The shifting interest is evident in an estimation that claims the long fiber thermoplastics market to surpass $3 billion by 2025.

Which industry verticals are leading the way in long fiber thermoplastics deployment?

The automotive and aerospace industries have emerged as major growth avenues for LFT market as thermoplastic components can be welded together instead of needing to be adhesively bonded or joined with mechanical fasteners as is the case with thermoset parts. This helps in considerable elimination of weight and cost of fasteners that is remarkably advantageous for the automotive and aerospace industries.

According to experts, the airline industry saves $1,000 for every pound that an airline can take out in a year. With regulations becoming stronger against carbon emission, auto manufacturers are looking for various means to make vehicles more lightweight which can result in major fuel efficiency and help achieve lowered carbon emission targets.

Automotive industry focuses on light weighting of vehicles to achieve carbon emission targets:

The regulatory landscape of the U.S. has issued a directive that by model year 2025, fuel economy standard should make a 60% improvement and provide 54.5 miles per gallon over the 35.5 MPG required of vehicles at present. Reducing the weight of vehicles is one of the most effective ways to accomplish fuel efficiency in vehicles – studies in fact, show that reducing the weight of a vehicle by 10% yields a 6% to 8% increase in fuel economy. One of the most promising lightweight composite materials to replace heavy steel on automobiles is thermoplastics.

Much of the light weighting of automobiles has already been put into place with obvious improvements like engine downsizing. But researchers are now progressing into newer realms of designing lightweight materials for the automotive industry that can be used in parts like doors, roof and trunk lids. The long fiber thermoplastics industry is poised to gain major impetus from such endeavors with researchers now turning to thermoplastics. This can also be attributed to the fact that the U.S. Department of Energy urged the automotive industry contenders to design parts that are lighter but maintain similar crash durability and performance as well as noise, vibration and harshness (NVH) performance. DOE also mandated the use of commercially available material systems so as to produce at least 20,000 vehicles per year.

Strategic collaborations and partnerships are being forged to develop materials that can help in achieving such loft emission goals which is subsequently adding further impetus to the long fiber thermoplastics market.

Citing an instance, Honda R&D Americas with support from the University of Delaware Center for Composite Materials has participated in such a project conducted by Clemson University Composites Center funded by the U.S. Department of Energy. The focus of the project is on the development of a car door with thermoplastics that is 42.5% lighter than standard OEM car doors but has the same structural excellence as an OEM door.

Aerospace industry: one of the forerunners in embracing long fiber thermoplastics

Aerospace equipment manufacturers had been some of the earliest adopters of LFTs, an array of products for aircrafts such as floor panels, avionic housing parts, rudders, horizontal tails and elevators made from thermoplastic composites are already in the mainstream. Distinct characteristics such as the repeatability of melting and reshaping of thermoplastic polymers and high level of material toughness makes LFTs a favorable choice for the aerospace industry that constantly demands lower-weight structures with improved damage tolerance.

With the expansion of the aerospace industry and the benefits of thermoplastics in the aviation sphere, the global long fiber thermoplastic market has much to gain from the aerospace applications.

What are some of the other lucrative domains that demand the deployment of thermoplastics?

Long fiber thermoplastics market has also garnered major profits from the product use in the sports and leisure industry. According to experts, consumers in the sports and leisure segment are less sensitive to the cost of the material as they are trying to win or perform at a higher level. If the material of the equipment can ensure better performance, consumers have been found to be willing to spend a lot more to capture the performance advantage.

As per estimates, long fiber thermoplastics industry share from sports & leisure application will surpass 30 kilo tons by 2025. Consequently, it is anticipated that long fiber thermoplastics market will benefit from the demand of such materials in manual scooters, bicycles, surfing boards and snowboards.

Long fiber thermoplastics market growth is still plagued by the barrier of lack of recognition, but this is expected to be lessening in the upcoming years. Thermosets are more widely understood and therefore garner a more considerable application base in the manufacturing world. But as thermoplastic processing techniques become more widely adopted and the positive return on investment more fully realized, long fiber thermoplastics market will register significant growth over 2019-2025.