Construction sector to lucratively drive insulated concrete form market over 2016-2024

Publisher : Fractovia | Published Date : March 2017Request Sample

Insulated concrete form (ICF) market is growing at a fast pace owing to its heavy demand in the hurricane and seismic-prone areas. ICF construction provides durability, strength, airtightness, and excellent sound insulation to the buildings. With growing consumer awareness toward wellbeing, uplifted living standards, and quality of life, the demand for energy efficient infrastructure is on a steady upsurge. MEA and Asia Pacific insulated concrete form industry is expected to penetrate deeply in the coming years, owing to the rise in disposable incomes in these regions and the positive approach toward new construction materials. According to Global Market Insights, Inc., ”Insulated concrete form market registering a revenue of USD 470 million in 2015, is projected to grow significantly at a CAGR of 8% over the period 2016-2024.

Global insulated concrete form market from industrial applications is expected to prominently drive the overall industry over the coming seven years due to increased consumer spending on industrial construction. The industrial sector is projected to grow at an annual rate of 10% over 2016-2024.

U.S. Insulated Concrete Form Market size, by application, 2013-2024 (USD Million)

With conventional energy resources getting exhausted, numerous manufacturers are shifting toward green buildings. Residential application accounted for a major share (55% of the total volume) in terms of revenue in 2015, and will continue to be the dominant segment driving the insulated concrete form industry. Accelerating global population leading to more residential construction development will further augment the industry growth. Almost 80% of the ICFs are used in low-rise residential construction, with a revenue estimation of USD 500 million by 2024.

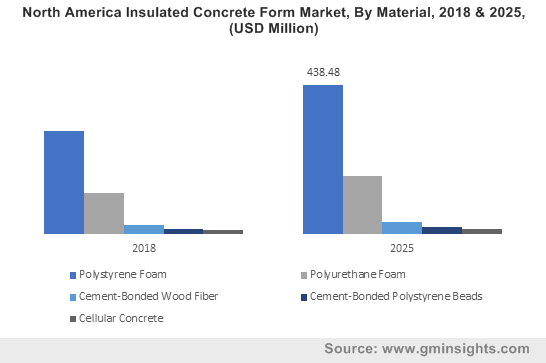

Geographically, North America insulated concrete form market led by the U.S. and Canada will exhibit substantial growth in the years ahead. Flourishing construction industry of Canada with a strong consumer urge for energy efficient building is fueling the regional demand. Approximately, 100 distributors of ICF systems serve the Canadian industry. Favorable energy saving policies initiated in the U.S. and Canada will influence insulated concrete form industry growth in these regions.

Polystyrene foams are mostly used in ICFs construction. Driven by the rising consumer requirement for features such as energy efficiency, comfort, structural stability, and cost effectivity in buildings, polystyrene insulated concrete form market is the leading segment driving the global market, accounting for more than 60% of the total volume in 2015.

Polyurethane foam ICF industry is also witnessing a heavy adaption in ICFs construction. With an estimated revenue worth over USD 100 million in 2015, polyurethane forms market is also expected to depict substantial growth over the coming seven years.

Initially, insulated concrete form industry faced acceptance issues due to low product awareness, initial costing, and weak regulatory support. However, the situation is improving with increasing population in developing nations clubbed with advanced development exercises.

Insulated concrete form market is highly competitive with multinational players sharing the business space. Some of the notable players for ICF industry include Airlite (Fox Blocks), BuildBlocks, Quad-Lock, Amvic, and Logix. The market is highly consolidated in North America owing to the presence of key manufacturers across the region.