Industrial robotics market to derive remarkable gains via automotive sector over 2017-2024, global industry to be characterized by innovative product launches

Publisher : Fractovia | Published Date : 2018-02-23Request Sample

As robots and other computer-assisted technologies take over tasks previously performed by manual labor, the global industrial robotics market is set to attain significant popularity across a diverse set of business domains over the forthcoming years. While unraveling the market dynamics of the overall industrial robotics industry, it is quite imperative to take note of a few reliable studies that highlight the prospective growth of this business space. A recently published study by the National Bureau of Economics Research and scholars from MIT and Boston University states that the swift escalation in research and development activities has led to the massive manufacturing of industrial robots. This enormous pace of automation has reportedly led to five human workers being replaced by a single robot during the time span of 1990 to 2007, something which explains the rise of industrial robotics market. Speaking in the similar context, the current global average of robot density in the manufacturing industries has reached 74 robot units per 10,000 employees, as per the figures published by a prominent non-profit organization, International Federation of Robotics. These figures go on to demonstrate the rising significance of industrial robotics market, which, as per reliable estimates, recorded a total remuneration portfolio of over USD 35 billion in the year 2016.

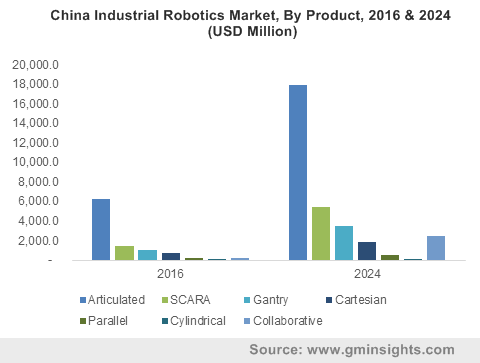

China Industrial Robotics Market, By Product, 2016 & 2024 (USD Million)

Over the recent years, the leading industrial robotics industry players have been concentrating on releasing advanced robots in order to simplify the prevailing automation tasks. For instance, Mitsubishi Electric Corporation has recently unveiled its smart-control artificial intelligence technology that would enable industrial robots to seamlessly grasp the changing conditions of target objects in real time. Furthermore, the optimum control algorithms of the technology would deploy deep reinforcement learning which would assist these robots in adopting conventionally difficult industrial tasks. Apparently, the aforementioned incidence provides further validation to the fact that such innovative product launches would indeed augment the revenue share of industrial robotics industry over the estimated timeframe.

How industrial robots have influenced the manufacturing procedures in automotive sector

In an era, which has been witnessing striking advances in automation, robotics, and artificial intelligence, the global automotive industry has lauded and readily embraced the emergence of industrial robots. Numerous prominent automakers across the world have been preferring robotic intervention in their production and assembly lines over the conventional methodologies. Owing to the rapid adoption of these high-tech robots by car manufacturers to enhance efficiency and precision of the production lines, the global industrial robotics market is estimated to witness massive demand from the automotive industry. Over the past few decades, the wide-scale deployment of computer-assisted technologies has altered the manufacturing processes of the global automotive sector- a factor that has been instrumental in boosting the industrial robotics industry share. It would be prudent to mention that the utilization of industrial robots has revamped the production and assembly lines making them more flexible, precise, and efficient. The growing prominence of industrial robots in the automotive domain can be comprehended by the statistics published by Robotics Industries Association. Apparently, the US-based trade group has claimed that the automotive players procured more than 50 percent of the total robots sold in the nation over the past few years. The aforementioned incidences validate the enhanced work output as compared to manual labor and underline the criticality of automotive sector as a significant customer of the industrial robotics market.

In addition to the aforementioned aspects, a host of technological innovations to enhance the capabilities of collaborative robots, robotic hand, robotic vision, and robotic painting has further impelled the growth prospects of the industrial robotics industry. Encouraged by such progressive tech advancements many leading automakers are apparently transforming their manufacturing facilities by deploying pathbreaking robots. For instance, the US-headquartered electric vehicle manufacturer, Tesla Inc has been extensively installing industrial robots across its Nevada and Fremont production units to accelerate its production speed. The robots utilized by Tesla are reportedly manufactured by renowned industrial robotics market behemoths, Fanuc Corporation and KUKA, and are used to perform perilous tasks such as lifting heavy chassis and delicately assembling battery trays. The firm has further installed new ramps to mount the robots over the production line, given that the entire manufacturing process would be managed and supervised by these robots. Needless to mention, the massive acceptance of robots by automotive industry would undeniably stimulate the growth potential of the overall industrial robotics market.

The competitive spectrum of industrial robotics market has been highly combative with numerous firms including Mitsubishi Electric Corporation, Fanuc Corporation, Denso Corporation, KUKA AG, Yamaha Motor Co., Ltd., and Kawasaki Heavy Industries Ltd making concerted efforts to overhaul their existing product spectrum. Apparently, the strategies adopted by these companies to meet the ever-increasing demand for product integration would be one of the pivotal factors that will drive industrial robotics industry share, which is forecast to exceed a total valuation of USD 80 billion by 2024.