Hoist Controller Market to be characterized by growing emergence of next-generation technologies, extensive demand for automatic hoists to catalyze the industry growth over 2018-2025

Publisher : Fractovia | Published Date : July 2018Request Sample

The robustly increasing demand for material handling equipment is considerably stimulating hoist controller market in recent times. The rapid industrialization across the globe is turning out to be beneficial for the hoist controller manufacturers, owing to the surging deployment of material handling equipment for boosting operational speed and efficiency. In applications that involve performing critical and heavy tasks where human intervention seems next to impossible, hoist controllers naturally find prominent deployment, catalyzing the overall hoist controller market expansion.

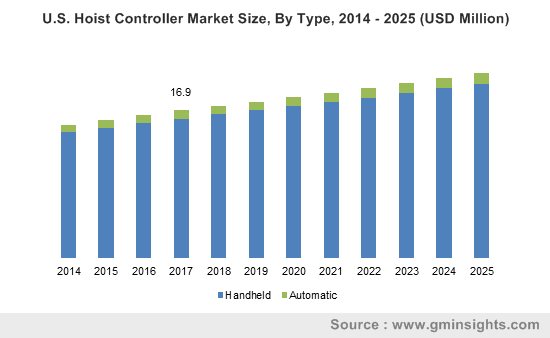

U.S. Hoist Controller Market Size, By Type, 2014 – 2025 (USD Million)

It has been observed that regional governments have mandated the use of cranes and elevators in order to maintain occupational safety of workers. In this regard, in order to comply with regulatory norms related to occupational safety, many of the companies in commercial as well as industrial sectors are extensively installing modern lifting systems, propelling hoist controller industry trends.

Traditionally, material handling equipment that were available a while back were not very user-friendly. However, a gradual change in technology trends have considerably changed the scenario, leading to the growing adoption of material handling equipment and consequently, a change of focus in the product development approach of players in hoist controller market. Recently, the German hoist and crane manufacturer, J D Neuhaus launched an innovative remote-controlled hoisting device, which can be used in places that are hard to access. Apparently, it can be effectively used for offshore and explosive environment applications, pertaining to the long-range operating capability remote control models. With the development of this electronic-based radio remote control, the German behemoth has thus set a benchmark for other hydraulic and pneumatic crane & hoist manufacturers.

The growing emergence of smart technologies and automation across various industrial sectors has brought about considerable modernization at the workplace. The incorporation of different types of sensors, positioning systems, and software in the currently manufactured devices has been helping giants achieve a dominant position in hoist controller industry. A few years before, crane maintenance and monitoring was highly dependent on manual labor, resulting in downtime risks and high maintenance cost. However, the implementation of smart and next-generation features in hoisting and crane devices has proved to be beneficial for the customers, enabling them to perform online monitoring task to check the status of a crane.

With the development of smart products, companies are trying to change the business scenario in hoist controller market. The continuous engineering innovations and upcoming technology trends in hoisting devices have been setting a new benchmark for the end-users of this market. The increasing automation in crane technologies is also likely to emerge as another possible trend across the construction, automotive, and metal processing industries, owing to the continuously surging labor costs. In this regard, the growing demand for crane services has encouraged leading participants in hoist controller market to capture more business space with a widespread product portfolio.

Validating the aforementioned fact, recently, Konecranes has added new single phase heavy-duty industrial hoist in its portfolio. This product has been forecast to be accepted by the end-users established in the area where 3-phase service is unavailable. This customer-centric product development approach of players in hoist controller industry will thus expedite the market growth over the years ahead.

While working in a heavy duty and hazardous working environment, precision and accuracy plays a vital role. However, at times, there may be chances of injuries due to lack of accuracy and precision during working operations. The need for operational safety and efficiency have thus led to the effective design and development of material handling and hoisting systems which can provide comfort to the operator. For instance, a year before, the leading manufacturer of material handling products and systems, Columbus McKinnon Corporation designed a comfort-fit pendant control rocker switch which can reduce the fatigue and hand strain of operators. The new design of material handling systems has been proving to be a productivity enhancer, having reduced workplace hazards.

The ergonomic and economic improvement in material handling controlling systems has been remarkably driving hoist controller market share in the last few years. The launch of remote controlled and automated product ranges is also generating substantial revenue across several geographies. With the shifting trends toward the adoption of highly advanced and next-generation controlling systems, the demand for these systems is likely to soar high. Powered by the surging deployment of highly innovative material handling switches, hoist controller industry will surpass a revenue collection of USD 104 million by the end of 2025.