Helical Screw Blowers Market to be characterized by energy saving potential and adherence to stringent ISO standards, APAC to be a promising growth avenue

Publisher : Fractovia | Published Date : 2018-06-13Request Sample

The global helical screw blowers market has gathered a substantial momentum in the manufacturing sector, largely attributed to the industrial demand for highly efficient, low noise and cost-effective products. The screw blowers provide continuous air supply with lower energy utilization and are more reliable, delivering a better performance than the traditional root blowers. The worldwide acceptance of screw blowers in power, food processing, steel and other such industries has spurred tremendous investment towards their development, in turn proliferating helical screw blowers market trends.

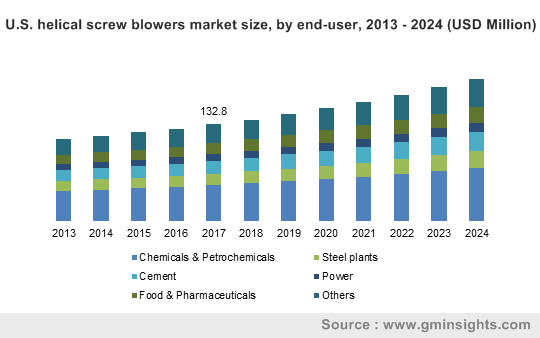

U.S. helical screw blowers market size, by end-user, 2013 – 2024 (USD Million)

The overall helical screw blowers market witnessed a remuneration of USD 785 million in 2017, with the prominent contributor being the chemicals and petrochemicals segment. In 2017, this segment procured 35% of the overall helical screw blowers end-use landscape. The screw blowers are used to direct, compress and thrust the various corrosive, explosive and inert gases generated in chemical plants and refineries.

Other significant applications of screw blowers include the pneumatic conveying of cement and fly ash, charging of kiln, blending and aeration of cement silos in cement manufacturing plants. They are likewise efficient in the discharge of granulated and bulky materials like grain, sugar, flour, powdered chemicals and dry cereals. The variety of applications for the helical screw blowers market can be derived from their sealed design which results in a very smooth air flow and limited leakage while moving both air and gas.

With growing inclination of companies to adopt cleaner and safer equipment which support the manufacturing processes, the International Standards Organization (ISO) had put forth a new class of air quality dedicated to the food and pharmaceuticals segment. The new standard is termed as Class 0 and is the most difficult air quality level to achieve, with the purpose of minimizing the oil contaminations in food processing, liquids, vapors and aerosols. The screw blowers adhere to the Class 0 standard owing to their oil-free design and this advantage will play a significant role in driving the helical screw blowers industry share. Oil-free operations also make screw blowers desirable in ventilation and air pollution control systems which require pure and clean air conveyance.

Atlas Capco manufactures ZS (VSD+) screw blower which is Class 0 certified has gained a remarkable popularity in the competitive hierarchy of helical screw blowers market. The blower is claimed to be easy to set up, has low noise levels and high reliability and monitors overall performance of the system along with service level indications, malfunction signaling, and safety shut down. The company promises a reduction in energy costs of up to 30% as compared to the conventional blowers.

Another prominent name in helical screw blowers industry, Kaeser Compressors, Inc. made it to the headlines with its new line of rotary screw blowers which are up to 35% more efficient the traditional blowers. These developments vividly underline the rich product landscape of helical screw blowers market.

Elaborating further on the product spectrum, the screw blowers using direct drive system are estimated to grow with a 6% CAGR over 2018-2024. The direct drive blowers have a simple drive system which reduces transmission losses due to absence of components like belts, pulleys, racks & pinions, etc. This essentially guarantees outstanding performance and energy savings. The belt-drive screw blowers will also accrue considerable share in the helical screw blowers market, despite low efficiency and more maintenance required. Belt driven blowers are preferred in heavy pressure applications as the belts and pulleys absorb vibrations, ensuring longer lifespan. The different areas of use for direct and belt driven blowers compiled with increasing R&D to develop more efficient systems will shape the dynamics of the helical screw blowers industry.

Regionally, APAC stands tall in the global share battle, backed by the rapid industrialization and huge amounts of funds allocated to industrial infrastructure development in countries like India and China. Factoring in the growing popularity of screw blowers to enhance air and material transfer in cement, steel, metal processing and food processing industries, the Asia-Pacific helical screw blowers market is expected to record a 6% CAGR over 2018-2024.

All in all, the worldwide helical screw blowers market is rather a dynamic competitive stage, with an anticipation of slew of tech-advanced products in the pipeline. Undoubtedly, the industry 4.0 revolution will bring a disruption of sorts in the competitive as well as the regional hierarchy of this fraternity. In terms of remuneration portfolio, the global helical screw blowers industry is anticipated to surpass the billion-dollar benchmark by 2024.