3 important trends reinforcing fluoropolymers additive market in 2019

Publisher : Fractovia | Published Date : 2019-06-10Request Sample

Owing to an extensive application scope across different types of coatings, lubricants, and printing inks, global fluoropolymers additive market is anticipated to witness remarkable growth prospects in the forthcoming years. The use of fluoropolymers additive have gradually expanded over a wide range of business verticals including consumer goods, automobile, aviation and aerospace which in turn have propelled the demand for products like polytetrafluoroethylene (PTFE) micropowders and perfluoroalkoxy micropowders.

Apparently, PTFE is an incredibly versatile material with a broad variety of applications, distinguished by its high melting point, low coefficient of friction, good abrasion resistance, and reduced stress cracking. Listed below are key trends driving the fluoropolymers additive industry with a consistent target base for PTFE:

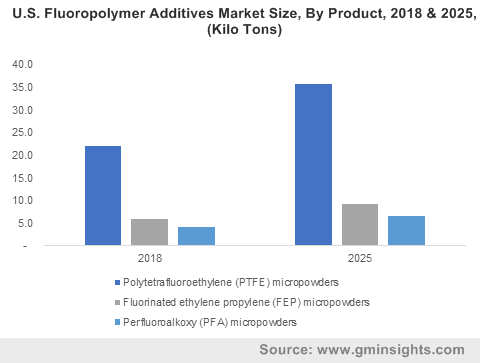

U.S. Fluoropolymer Additives Market Size, By Product, 2018 & 2025, (Kilo Tons)

1. Food Applications: PTFE is widely known for providing a slippery surface to products which make it perfect for use in making cookware. Today, many commercial brands are offering various lines of cookware that are coated Teflon, which is based on PTFE, in order to prevent food from sticking to the pans and pots. This has substantially reduced the need for cooking oil because these pans and pots are naturally ‘non-stick’.

Undoubtedly, PTFE coatings are beneficial for not only homes but also restaurants, where food must be prepared quickly while pots and pans require fast cleaning and can be returned easily to active use in no time.

According to prominent studies, even the U.S. Food and Drug Administration (FDA) has found PTFE based Teflon acceptable for conventional kitchen use. Globally, cookware sector has received a major boost in the past few years due to expanding fast-food segment and rising population. Several companies are extensively creating a new set of products for their consumers, invariably generating revenues for fluoropolymers additive industry.

Aerospace Applications: Generally, products used in the aerospace industry have to pass rigorous testing and demanding operating conditions. PTFE coatings and plastics used in the aerospace industry should be of highly quality, extremely specified, and enhance toughness and durability of components.

An example where PTFE is crucial is its application on the leading edges of the aircraft wings, which are the flaps used to slow an aircraft while landing. Supposedly, the substance is extensively deployed in applications where friction and fluid compatibility are of the utmost importance under high and low-temperature conditions.

In 2017, Freudenberg Group had introduced a new line of PTFE seals designed to meet exacting aerospace sector requirements. Sealing in airplanes play a vital role in weathering extreme altitudes and temperature changes.

Continuous demand for aerospace sealing solutions resulting from growing airline fleets worldwide will certainly fuel the expansion of fluoropolymers additive market. Growth of the aviation sector can be surmised from the fact that in 2018, Airbus alone had delivered around 800 aircraft to customers and had received nearly 747 new orders in the year.

2. Automotive Applications: Due to high reliability and being extremely suitable for processing at high or low temperatures, PTFE are witnessing substantial demand within automobile industry. PTFE thermoplastics are able to maintain exceptional material properties in demanding conditions and are used in making parts such as outside edge of air compressors.

Demonstrating the importance of the fluoropolymers additive industry for the automotive sector, PTFE coatings are used on lock systems, steering column interlock plungers and seatbelt springs, among others. The material enhances the performance of components as well as reliability of the end-products.

With more than 95.6 million vehicles produced in 2018, automobile sector represents a steadily growing global customer base for PTFE-based products and the overall fluoropolymers additive industry.

Key manufacturers like Daikin Industries, Maflon SpA, Micro Powders, Shamrock Technologies, and Solvay are some of the leading market players focusing on advanced fluoropolymer products and bringing forth a spate of innovations in the industry. Reports estimate that the global fluoropolymers additive market will surpass a valuation of USD 1.9 billion by 2025.