APAC to majorly drive global flow chemistry market over 2016-2024, India and China to be the key revenue pockets

Publisher : Fractovia | Published Date : 2017-04-28Request Sample

In recent years, flow chemistry market has been exhibiting exponential growth with the development of new and enhanced chemical processes subject to efficient resource optimization. In terms of operational cost, installation cost, improved reaction control, reduced capital cost, and high capability of heat & mass transfer, flow reactors have proved to be much more beneficial than batch reactors. In addition to this, many of the challenging reactions in batch reactors can be easily carried out in flow reactors, which will boost flow chemistry industry over the years ahead.

As per the report by Global Market Insights, Inc., “Flow chemistry market, having had a revenue collection of USD 900 million in 2015, will cross an annual growth rate of 10% over the period of 2016 to 2024.” Due to the precise and effective result-oriented approach of the flow chemistry process along with its capability to improve productivity, most of the pharmaceutical and chemical companies have been adopting this technology of late.

U.S Flow Chemistry Market share, by end-user, 2013-2024 (USD Million)

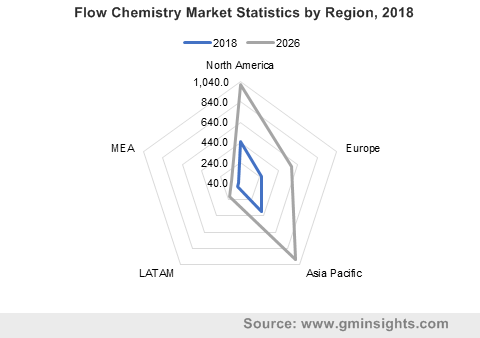

Pharmaceutical end user segment will register lucrative growth in flow chemistry industry over the coming timeframe, owing to the fact that this sector implements this process on a large scale, subject to its key benefits such as high safety measures and low operational cost. Moreover, many of the industry giants are adopting this technology for the manufacture of drugs and medicines. The pharmaceutical sector is expanding its business space lucratively across the U.S., owing to which North America flow chemistry market will register an annual growth of more than 9% over the coming years of 2016 to 2024. U.S. will be the prominent revenue contributor toward North America regional share.

Asia Pacific flow chemistry market dominated the global revenue share in 2015 and will exhibit flourishing growth prospects over the coming seven years. Supportive governmental norms and low initial investment required to establish a manufacturing base across APAC countries have attracted more market players, which, in turn, will generate significant revenue for flow chemistry industry over the years ahead. India and China will contribute significantly toward regional flow chemistry industry growth, owing to the presence of myriad chemical manufacturers in the region.

This technology is extensively used in biodiesel production plants, owing to its superior efficiency, minimal carbon emission, and less requirement of raw material. This, in turn, will boost the need for flow chemistry equipment considerably. The aforementioned advantages will lead continuous stirred tank reactor (CSTR) to be prominently used in various petrochemical and chemical sectors. CSTR dominated the product landscape of global flow chemistry market in 2015 and is anticipated to witness a noticeable growth rate over the coming seven years. These types of reactors are arranged in a series combination, which leads to reaction efficiency improvement. It also requires less installation space as compared to batch reactors.

Microreactor is another lucrative product segment in flow chemistry industry, which will exhibit the highest annual growth rate of more than 15% over the period of 2016 to 2024. Implementation of this system helps in controlling the heat reaction, as it has superior heat and mass transfer properties. Microreactor products are also prominently used for industrial and academic research activities. In addition, the ongoing research and technology advancements in this system will impact flow chemistry market share positively.

Many industry giants are struggling to achieve the top business position owing to the continuous fluctuation in product costs as well as the introduction of new advanced products in the market. Industry participants have been collaborating with various multi-national companies operating in pharmaceutical, petrochemical, and chemical sectors to achieve lucrative profit margins. The key players in flow chemistry market are ThalesNano Nanotechology Inc., Vapourtec Ltd., Uniqsis Ltd, AM Technology, Koninklijke DSM N.V., FutureChemistry Holding BV, Chemtrix BV.