Analyzing automotive robotics market in terms of the application landscape, assembly operations to emerge as a major growth avenue over 2017-2024

Publisher : Fractovia | Published Date : 2017-09-27Request Sample

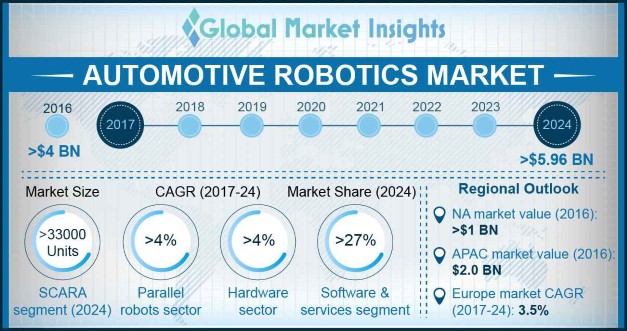

The latest news that automotive robotics market is ablaze with is ABB’s acquisition of B&R. Somewhere toward the end of the first quarter of 2017, ABB Group, one of the most reputed players partaking in automotive robotics market share, took over B&R, supposedly the largest independent provider of open-architecture, software-based machine and automation solutions, with an aim to create an unparalleled, comprehensive service offering with regards to industrial and manufacturing automation. The move has been touted to be one of ABB’s most lucrative acquisitions that would sizably impact automotive robotics industry share, given that the latter is an unrivaled player in industrial automation, while ABB is renowned to have achieved milestones as far as process automation, electrification, digitization, and robotics are concerned. Inherently characterized by the escalating advancements in robotics technology, in conjunction with the robust growth depicted by the automotive sector, automotive robotics market indeed is likely to chart a lucrative growth map in the years ahead, with a revenue projection of close to USD 6 billion by 2024.

U.S. Automotive Robotics Market Size, By Product, 2013 – 2024 (USD Million)

An insight into the application spectrum of automotive robotics market:

Automotive robotics industry outlook from the welding domain

The welding process is reportedly one of the toughest production processes in the automotive cosmos, and any excess involvement of humans in the operations may plausibly lead to musculoskeletal disorders. The application of robotics in the welding procedure has profound significance, given that the automated bots would keep laborers away from the welding and paint fumes, which would considerably stimulate automotive robotics market share.

As the degree of automotive manufacturing rises to an unprecedented level, the domain would command the prevalence of faster and highly efficient operations, which would lead to the deployment of numerous bots in applications such as arc welding and spot welding. In consequence, this would be responsible for minimizing the downtime for production to quite an appreciable extent, subsequently translating into significantly high profit margins for automotive companies, and by extension, providing a positive boost for the growth path of automotive robotics industry. Another adjoining factor that is responsible for the propulsion of automotive robotics market size from welding applications is the availability of numerous tools that are designed to minimize the maintenance requirement. The numerous product categories that are encompassed by automotive robotics market are inherently useful in the welding process, some of which are enumerated below:

- Huge bots generally possess a longer hand-reach ability and high payload capacities, on the basis of which they can easily be used to spot and weld car body panels.

- Smaller bots are designed for welding sub-assemblies – mounts, brackets, etc., subject to their limited reach ability and compactness.

- Slim robots are particularly designed to conserve the manufacturing floor space, by lowering the machine footprint.

Automotive robotics industry boasts of a wide product spectrum, that can be effectively utilized to ease the welding process to quite an appreciable extent. Considering the vast expanse of the automotive sector and the projected vehicle production estimates, it would seem as though automotive robotics market would generate substantial revenue from welding applications, given the accuracy of the process and its importance in the overall production.

Automotive robotics market outlook from the assembly domain

Assembly operations hold pivotal importance in the overall automobile manufacturing process. Automakers have been deploying automation for assemblies on a significantly large scale, pertaining to the factors of safety, high quality, and capacity. In addition, robots help to reduce the waste caused due to frivolous human errors, which would apparently lead to the lesser variability in the assembly. In consequence, this would be responsible for controlling the process at every stage of the assembly line in addition to maintaining the consistency in the time required for every process, which would indisputably lead to the growth of automotive robotics industry share from assembly operations.

The profound significance that robotics holds in assembly applications is quite vivid from certain statistics. In consonance with the estimates compiled by analysts, assembly operations held more than 15% of the overall automotive robotics market share in 2016. Currently, the automotive manufacturing sector holds the record of having almost 90% of their final assembly operations performed with the help of automation. Furthermore, it is fundamental to mention that the demand for automation in body-in-white and powertrain assembly applications is indeed scaling tremendous heights, thereby augmenting automotive robotics industry size from assembly applications.

It has been observed that the usage of SCARA bots are quite commonplace in high-speed assembly operations due to the increasing demand for optimized productivity and zero bottlenecks. Automobile assemblies demand the perfection in tasks such as windshield installation, wheel mounting, and screw driving, all of which have been deemed as viable contenders for automation. The deployment of robots for mobilizing smaller assembly components to fabricate larger ones is also prevalent in recent times – a move which is likely to stimulate automotive robotics market from assembly line operations.

The utilization of automated robots in automotive manufacturing has not been a present-day occurrence. Bots had been deployed by manufacturers post the Second World War – the period that witnessed a slew of technological inventions and integrated industrial concepts. From then on commenced the commercialization of automotive robotics industry. And now, in 2017, robotics forms an inherent segment of the automotive manufacturing process. With accelerated technological advancements in place, in tandem with the escalating demand for automation in vehicle production, it comes as no surprise that automotive robotics market size has been forecast to surpass 210 thousand units by 2024.