Asphalt mixing plants market exhibiting a remarkable growth potential from construction application, Asia Pacific to accelerate regional landscape over 2017-2024

Publisher : Fractovia | Published Date : 2017-08-09Request Sample

The escalating growth of the construction and infrastructure sectors is one of prominent factors stimulating asphalt mixing plants market, given that asphalt is one of key raw materials used in road construction. Strictly speaking, around 70% of overall asphalt production is consumed for road developments. Taking into consideration, the large-scale use of asphalt for road construction, industry giants are utilizing innovative technologies to reduce labor cost, machine wear, and fuel consumption. Ammann Research and Development Center is continuously launching new products in all corners of the world for diverse kinds of construction applications. To fulfill the increasing need of asphalt paving is likely to influence asphalt mixing plants industry size positively. As per the market study, asphalt mixing plants market collected a revenue of USD 6.6 billion in 2016.

There has been considerable ongoing research pertaining to the improvement in road quality by means of using non-biodegradable products – such as introducing aggregates into the asphalt mixture. In addition, non-biodegradable products also help to reduce toxic content from the environment. A recent study by researchers might actually help this endeavor - researchers suggest that cigarette butts can be added to the asphalt mixture, as they contain plenty of toxic chemicals, the disposal of which may contaminate open spaces and waterways and threaten the aquatic organisms. When added to asphalt bricks, the cigarette might actually help to strengthen them. This study has been deemed to be one of the most innovative trends in asphalt mixing plants market in recent times. Furthermore, it is noteworthy to mention that the deployment of environment safety norms will generate lucrative opportunities for asphalt mixing plants market giants over the years ahead. The major players in asphalt mixing plants industry are Benninghoven, AMMANN Group, Nikko Company Ltd, ASTEC, MARINI S.p.A, LINTEC Corporation, DELTA Group, and Speedcrafts Limited.

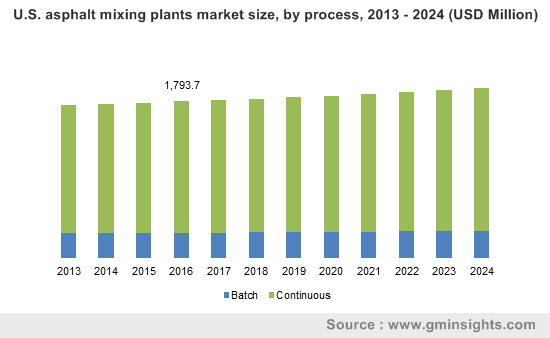

U.S. asphalt mixing plants market size, by process, 2013 - 2024 (USD Million)

Considering that asphalts possess greater benefits such as durability, flexibility to accommodate imperfections, and surface hardness as opposed to concrete, an increasing demand for the former has been observed since the last few years as compared to the latter, which will augment asphalt mixing plants industry share. Also asphalt based roads possess a unique capability to withstand heavy vehicles. Besides, automakers are developing high end luxurious vehicles, owing to the changing consumer lifestyle and growing modernization across the globe. In addition to this, increasing spending capabilities are likely to fuel the requirement for passenger and personal cars, leading to an increased rate of traffic, which will demand the existence of strong roads, thereby propelling asphalt mixing plants market. In the light of the exponentially rising automobile demand, the governments of various countries are investing heavily in developing highways, which will further boost asphalt mixing plants market share over the years ahead.

Most of the automakers are expanding their regional presence across Asia Pacific, pertaining to the growing consumer base. The governments of various Asian countries such as India, China, Japan, Malaysia, and Thailand are investing a huge amount of capital to improve road infrastructure. As per estimates, in 2016, Asia Pacific asphalt mixing plants industry accounted for a revenue of USD 2.5 billion.

Recently, China-based asphalt mixing plant industry giant, D&G technology, announced that it was glad to state that the company is likely to procure profits from the surging number of road construction projects in China as well as other countries. Apparently, as compared to the last year, the company witnessed a 53% hike in the profit up to 30th June 2017. Pertaining to the deployment of national environmental protection policies by the Chinese government, the demand for recycling asphalt mixing plants has considerably increased. The CEO of D&G group, Ms. Glendy Choi stated that the increase in road construction projects not only across China but also across the ‘One Belt One Road’ countries have generated huge opportunities for manufacturers in asphalt mixing plants market. She has also added that the investment in infrastructure is one of the lucrative factors influencing the economic growth of a nation, which can be substantially bettered through asphalt roads. Speaking of which, asphalt mixing plants industry collected a revenue of USD 5.5 billion in 2016 from road construction application.

Pertaining to the energy efficiency factor, asphalt mixing plant technology has been witnessing the trend of rental asphalt plant (RAP). Companies such as Amomatic have been undertaking steps to fulfill the client demands for rental plant owing to the subsequent reduction in huge initial investments in asphalt plant. Initiatives such as these are likely to promote the rental plant strategy, and eventually stimulate asphalt mixing plants market size over the coming years.

Continuous technological innovations and investments in R&D activities are slated to become fruitful for asphalt mixing plants industry players to sustain their leading position over the years ahead. Most of the behemoths operating in asphalt mixing plants market have been turning to acquisitions to enhance their product diversification. In 2014, for instance, Ammann acquired the leading German concrete mixing plant manufacturer Elba-Werk. In 2013, Ammann had also installed a manufacturing plant in collaboration with Apollo India Private Ltd, where asphalt pavers, asphalt mixing plants, and Apollo soil compactors are manufactured. Globally, asphalt mixing plants market is likely to depict an upward growth graph, with a CAGR estimation of 1.4% over the coming seven years.