APAC 3D Printing Equipment Market to gain substantial revenue via automotive applications over 2016-2024

Publisher : Fractovia | Published Date : 2017-04-21Request Sample

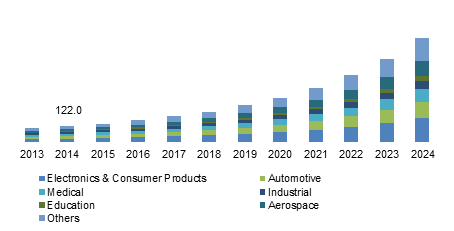

3D printing technology has earmarked its footprints globally across myriad end-user industries. 3D printing equipment market will carve a profitable roadmap in the years ahead subject to the shifting trends toward rapid prototyping, a technique that is extensively used in the medical and pharmaceutical sectors to manufacture artificial living organs such as liver and heart. In addition, 3D printing is extensively used to create dental crowns in root canal treatments, which will favorably influence 3D printing equipment industry size. As per the report by Global Market Insights, Inc., “Worldwide 3D printing equipment market was worth USD 4 billion in 2015 and will exhibit a CAGR of about 14% over the period of 2016 to 2024.”

Escalating investments by consumers for superior quality education will directly affect the sales of professional 3D printers & desktops, thereby augmenting 3D printing equipment industry growth. Manufacturers use various techniques such as selective laser sintering, polyjet, stereolithography, FDM, and colorjet to develop 3D printed parts. Selective laser sintering (SLS) 3D printing equipment market will exhibit an annual growth rate of about 15% over the years ahead, owing to its surging requirement across the automotive and aerospace sectors. This product offers excellent features such as high quality strength, superior complexity, and functionality.

U.S. 3D Printing Materials Market Size, By End-User, 2013 - 2024 (USD Million)

Most of the industry giants are focusing on the development of high quality products to meet the ever-growing demand. Cost effectiveness is one of the key growth strategies adopted by business competitors. Recently, Proto Labs added the polyjet technology to their industrial 3D printing services, which reduces the investment in tooling. As per a reliable study, polyjet based products covered more than 35% of the global revenue share in 2015 and are predicted to record substantial growth rate over the coming seven years. The growth can be attributed to its capability to produce an ultra-thin printed coat between 16 to 30 micrometers. It is also very feasible to manufacture prototypes with smooth surfaces and minute detailing. In addition, it also prints the components and parts of a model that comprises dissimilar materials, which will collectively drive 3D printing equipment market size.

3D printing materials are extensively used across the various end-use sectors such as defense, aerospace, medical replacement, architecture, and automobile. The automotive sector across Asia Pacific has been significantly expanding over the years, which will stimulate Asia Pacific 3D printing materials market share lucratively over the period of 2016 to 2024. Growing technological innovations in the pharmaceutical and medical sectors will fuel Asia Pacific 3D printing equipment industry growth. India, China, Japan, and Indonesia are anticipated to the prominent regional revenue contributors.

NASA is using 3D printing technology to manufacture futuristic astronaut spacesuits, as 3D printed metal fabric is foldable, highly heat resistant, strong, and reflective. Metal 3D printing materials industry is anticipated to register an annual growth rate of 17% over the coming years of 2016 to 2024, owing to the growing product demand across automotive and aerospace & defense sectors. The popularity of 3D printing across these sectors will also stimulate 3D printing equipment industry share over the coming timeframe. In addition, the governments of most of the countries are investing heavily in research and development activities in aerospace and defense, primarily to strengthen their national security base.

3D printing is massively utilized in the aerospace sector. The governments across the globe are striving to enhance their aircraft manufacturing base subject to the rising demand for air transportation. As per reliable statistics, the volume of total passengers carried by airlines will rise from 5.5 RPK billion in 2013 to more than 15 RPK billion by 2033. This in turn, will boost the revenue share of global 3D printing equipment market.

The notable participants in 3D printing equipment market are Concept Laser GmbH, Arkema S.A., Höganäs AB, Arcam AB, 3D Systems, Inc., EOS GmbH Electro Optical Systems, Solidscape, Voxeljet AG, EnvisionTEC, ExOne, Optomec Inc., SLM Solutions, Royal DSM N.V, Stratasys, Ltd., LPW Technology Ltd.